Nowadays, the most developed field of robot arms in every field is the industry and medicine sector. Robot arms work with an outside user or by performing predetermined commands. The work done to meet these needs makes life easier every day, and these studies are concentrated in robotic arm studies. Today, technology is developing in the same direction in line with rapidly increasing human needs. Robot Arm Control with Arduino by Abdullatif Baba This robot is about 4 kg in weight, and it is capable of picking and placing a book of weight one kg.s. RFID is used for identifying the books and it has two IR Sensors for detecting the path.

SCARA ROBOT WORKING PDF SOFTWARE

Software such as AVR Studio is used for programming, PROTESUS is used for simulation and PROGISP is used for dumping the program. The prototype consists of robotic arm along with grippers capable of moving in the three axes and an ATMEGA 8 microcontroller. The trend seems to continue as long as the robotics technology meets diverse and challenging needs in educational purpose. The use of robots in library is becoming more popular in recent years. The mathematical modeling and its results in MATLAB are best explained through this paper.ĭesign and Fabrication of Pick and Place Robot To Be used in library by Anusha Ronaki M.Kranti Professors, Department of Mechanical Engineering,Ĭalculated from CAD Software are compared with results obtained from MATLAB.

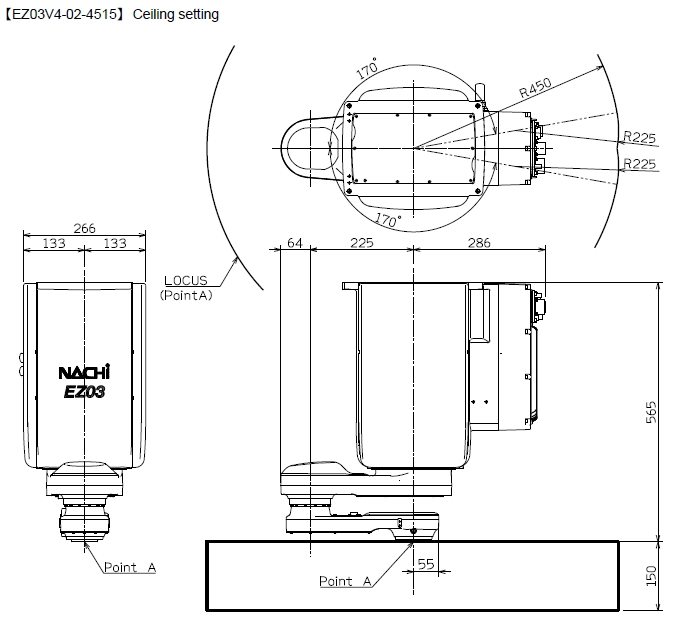

The results of joint positions and joint velocities The Kinematics of Robot is also explained in the simplest way. The SCARA Robot with four degrees of freedom is modeled in CAD Software. This research study describes the study of SCARA Robot for deburring operation of circular profiles. Modeling, Simulation and Analysis of SCARA Robot for Deburring of circular components by PVS Subhashini, N.V.S Raju and G. This sort of robot was created to increase the speed and repeatability of PICK & PLACE TASKS from one spot to another, as well as to speed up and improve assembly stages. The SCARA robot is a four-degree-of-freedom manipulator.

SCARA configurations are known for their fast speed, low maintenance, great repeatability, and sturdy architecture. Robotic arms used in assembly and production processes help to eliminate human error and increase production rates. The SCARA robots' performance, which included a large working area in the x-y plane, a suitable height in the z axis, and low sensitivity for load speed, positioning, and control accuracy, allowed them to be used in electronic printed circuit assembly, as well as the automotive and home appliance industries. SCARA robots, developed in the early eighties, represent a breakthrough in assembly automation (Makino, 1980). Keywords SCARA, Robotics, Fabrication, Automation, Arduino, Graphic User Interface (GUI), Kinematics, Degree of Freedom (DOF). By changing the program of the end-effector this robotic arm can be used in vast applications but mainly it can be used in the automatic assembly lines This robot is having 4 DOF and can be controlled by a Graphic User Interface that features both Forward and Inverse Kinematics control. Here controlling of the robot has been done by using NEMA 17 Stepper Motors and Arduino UNO. The main objective of this project was to develop a low-cost robotic arm that can be used for Pick and Place operations.

SCARA ROBOT WORKING PDF MANUAL

Robotics is becoming popular and has achieved great success in the last few decades but automation isnt cheap so everyone cannot afford to transform his unit from manual to automatic. SCARA robots are among the most widely used robots in the industry due to their high accuracy and inherent rigidity.

National Institute of Technology, Srinagar, KashmirĪbstract This report deals with the Design and Fabrication of a Selective Compliance Articulated Robot Arm (SCARA). Rizwan Ul Haq1, Umashankar Kumar2, Naveen Kumar3, Yash Baranwal4 Students, Bachelor of Technology, Mechanical Engineering, Design and Manufacturing of Low Cost SCARA Robot

0 kommentar(er)

0 kommentar(er)